Get a clear wellbore in one pass with Quantum Downhole’s Concentric Coil Milling System

The Concentric Coil Milling System (CCMS) clears wellbore obstructions such as scale, frac balls, frac seats or plugs. Quantum’s CCMS operation integrates CIRCA Pro Coiled Tubing Simulation Software with CTRAN for industry-leading multi-phase flow and solids transport modelling to determine the best program for your operation.

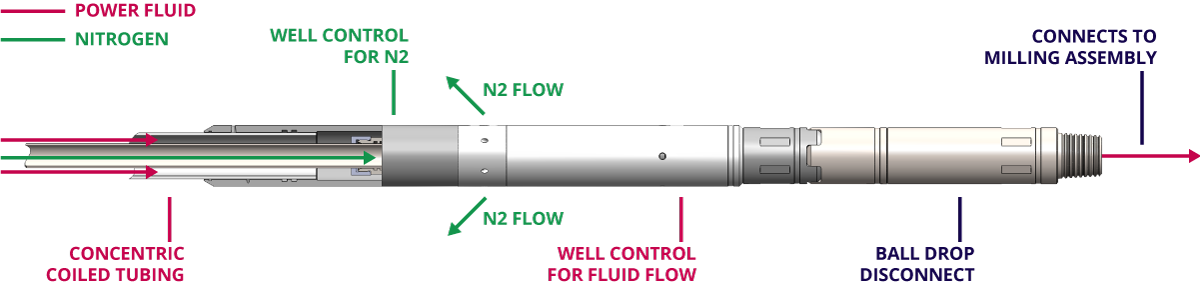

The BHA includes a patented downhole connector, release tool, jar and milling assembly able to clear downhole obstructions to get your operations running optimally. BHT and BHP recorders can be included depending on the application, scope of work and your operational objectives.

The CCMS design has a pathway that allows only fluid to the mud motor extending the life of the motor, creating optimal torque output and consistent port and plug milling time. The concentric coiled tubing and milling assembly system allow separate nitrogen and power fluid paths that can be adjusted independently to reduce overall nitrogen usage. Check valves and redundant disconnects in the BHA prevents inflow and maintains well control. Improved cuttings and wellbore material circulation, reduces operational risk.

All this translates into a consistent cleanout operation and a clear wellbore in one pass.

Find out more about how Quantum’s CCMS can reliably clear horizontals in a predictable operation.

403.450.8280