Check out the SPE Paper

Three-Stage SAGD Liner Intervention to Remediate a Liner System

The Challenge

This SAGD well was running smoothly, but underperforming. It had poor temperature conformance and typical completion design limitations (uneven distribution of drawdown points), making it an ideal candidate for a tubing deployed ICD system. It was converted from a uniform, high open flow area lateral to a segmented, pressure drop design to further optimize production.

The Operator in consultation with West Rock Energy Consultants suggested a cleanout followed by a gauge run. Quantum advised their JetVak™ Well Cleanout System. Quantum also confirmed the ability to run a gauge mill on Quantum’s concentric coil to drift the liner following cleanout in preparation for the installation of a remedial liner system.

The Operator in consultation with West Rock Energy Consultants suggested a cleanout followed by a gauge run. Quantum advised their JetVak™ Well Cleanout System. Quantum also confirmed the ability to run a gauge mill on Quantum’s concentric coil to drift the liner following cleanout in preparation for the installation of a remedial liner system.

Quantum’s JetVak is a patented system that simultaneously vacuums away fluidized wellbore materials, with guaranteed positive circulation, while gathering continuous inflow data. In this case, the JetVak operation was able to quantify the location and volume of solids in the liner.

The JetVak well cleanout system is a concentric coiled tubing assembly that includes an engineered jet pump and jetting head. The rotating jetting head is speed governed to maximize energy to the jetting force that fluidizes wellbore materials. The remainder of the power fluid activates the jet pump that artificially lifts the slurry to surface.

Prior to the operation, Quantum completes a technical program that includes the jetting design, chemical program, and hydraulic artificial lift modelling. During the operation, a recorder installed in the BHA logs downhole BHP and BHT while a Quantum technician at surface gathers oil, water and solids cuts for reporting.

For a cleanout intended to prepare for liner repair or installation in a SAGD producer, the operation needs to accommodate for the viscosity of bitumen and the risk of solids inflow during the operation. Quantum’s chemical injection program is selected to suit the downhole environment and then optimized during the operation to limit chemical usage and enhance effectiveness. Quantum’s technical program generally specifies that the JetVak lifting rate be higher than the fluid jetting rate to optimize the operational times and inflow to the BHA. The jetting configuration is based on the characteristics of the well and concentric coiled tubing design. Fluid may be pumped down the casing to maintain positive pressure on the failed region of the liner, this mitigates the potential for solids inflow throughout the remedial operation

The JetVak operation results allowed a gauge mill to reach maximum depth without issue:

SAGD wells typically have enough BHP to support aggressive jetting and vacuuming. Quantum recommended in the technical program that the BHA run fluid underbalanced to draw out the largest quantity of solids as quickly as possible. The JetVak operation ran with a higher lifting rate than the fluid jetting rate, and the BHA ran underbalanced for the full run. The jetting rate was regulated, and averaged 35.3 L/min. Most of the jetting power or force was directed outwards to thoroughly wash the liner walls and slots. Gross lifting rates averaged 60.3 L/min, resulting in an underbalanced rate of 25 L/min (36.0 m3/day). Over the 15.5-hour JetVak operation, the total volume of solids lifted was confirmed at 0.75 m3.

Following the cleanout, the workover incorporated a milling BHA used as a gauge ring. The sub-assemblies installed in the BHA included a disconnect, jar, mud motor, centralizer, bit box, twister bit mill. The gauge mill run went smoothly, with minimal weight loss throughout the lateral. The operation experienced no tags and no need for bit rotation. While the BHA was being pulled out of the well, friction-reducer was spotted to aid in the installation of ICDs and swell packers.

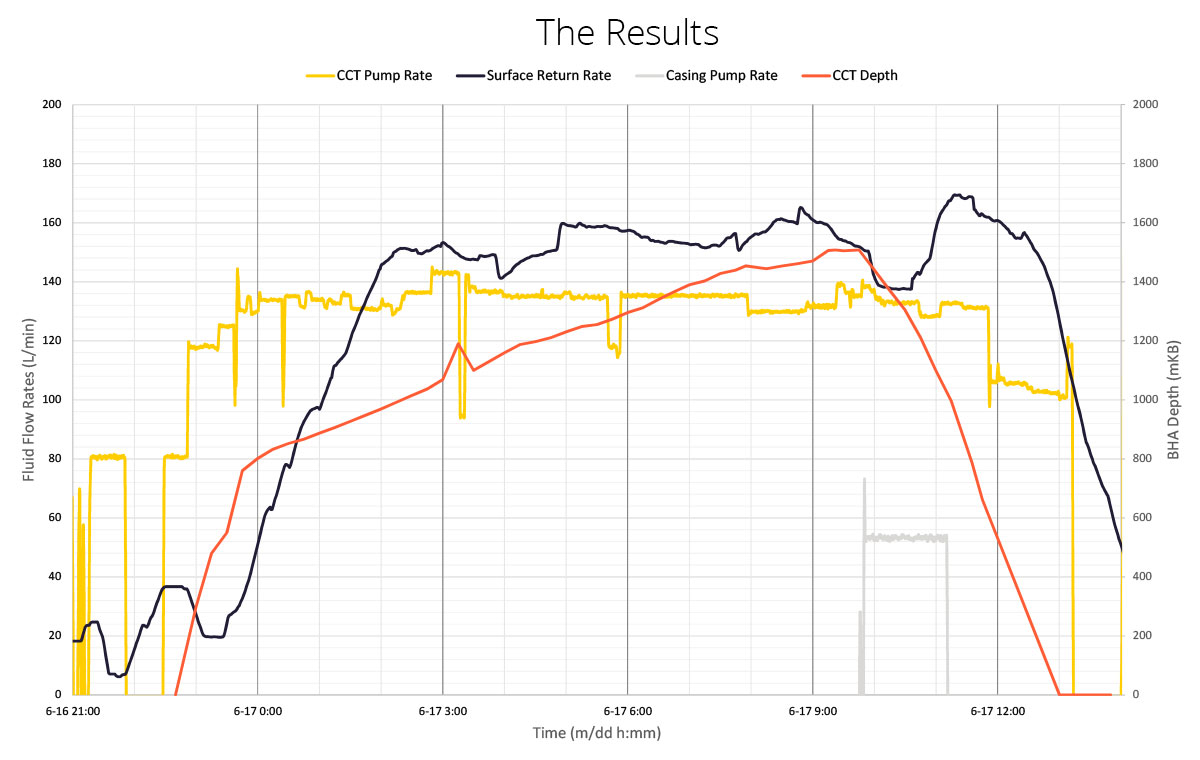

The Operator successfully ran 25 isolation packers with 10 mm overall clearance to a planned depth across the entire 734 m of the lateral. The success of the installation was attributed directly to the preparations from the JetVak cleanout and gauge mill run (see Figure below for surface return rates).

Three months following the recompletion, the net oil production increased 143%, from 70 m3/day to 170 m3/day and the SOR is down from 4.0 to 1.5.

| JetVak Operational Summary | |

| Maximum depth | 1515 mKB |

| Formation | Lloydminster |

| BHT | +/- 200°C |

| BHP | 3000 kPa |

| Average jetting rates | 35.3 L/min |

| Average gross lifting rates | 60.3 L/min |

| Average underbalanced lifting rates | 25 L/min |

| CCT size | 60.3 mm |

| Average bottoms-up time | 12.8 min |

| Volume of solids | 0.75 m3 |

| Maximum gross solids cut | 0.2% |

| Maximum gross oil cut | 18% |

| Cleanout time | 23.0 hours |

| Gauge mill operation time | 6.0 hours |

“By pre-planning the cleanout and wellbore evaluation with pro-active modelling and stream-lined rig operations, we are able to mitigate risks while also maintaining efficiency with regards to time, costs, and overall final results. Quantum Downhole provided the expertise through knowledge and experience, as well as the operational equipment and 24-7 leadership to make this workover a success.”

Ryan Cross

Vice President, Oil Sands

West Rock Energy Consultants Ltd.